Every experienced plumber knows that piping options are like wrenches: plenty will get the job done, but there's always a favorite for a reason. When evaluating PEX vs CPVC for your plumbing projects, consider these key differences for your business.

| Feature | PEX (Cross-linked Polyethylene) | CPVC (Chlorinated Polyvinyl Chloride) |

|---|---|---|

| Flexibility | Highly flexible, fewer fittings needed, easier for tight bends. | Rigid, requires more fittings and solvent cement for changes in direction. |

| Installation | No glues or solvents, quick connections, less labor intensive. | Requires glues and curing time, weather-sensitive connections. |

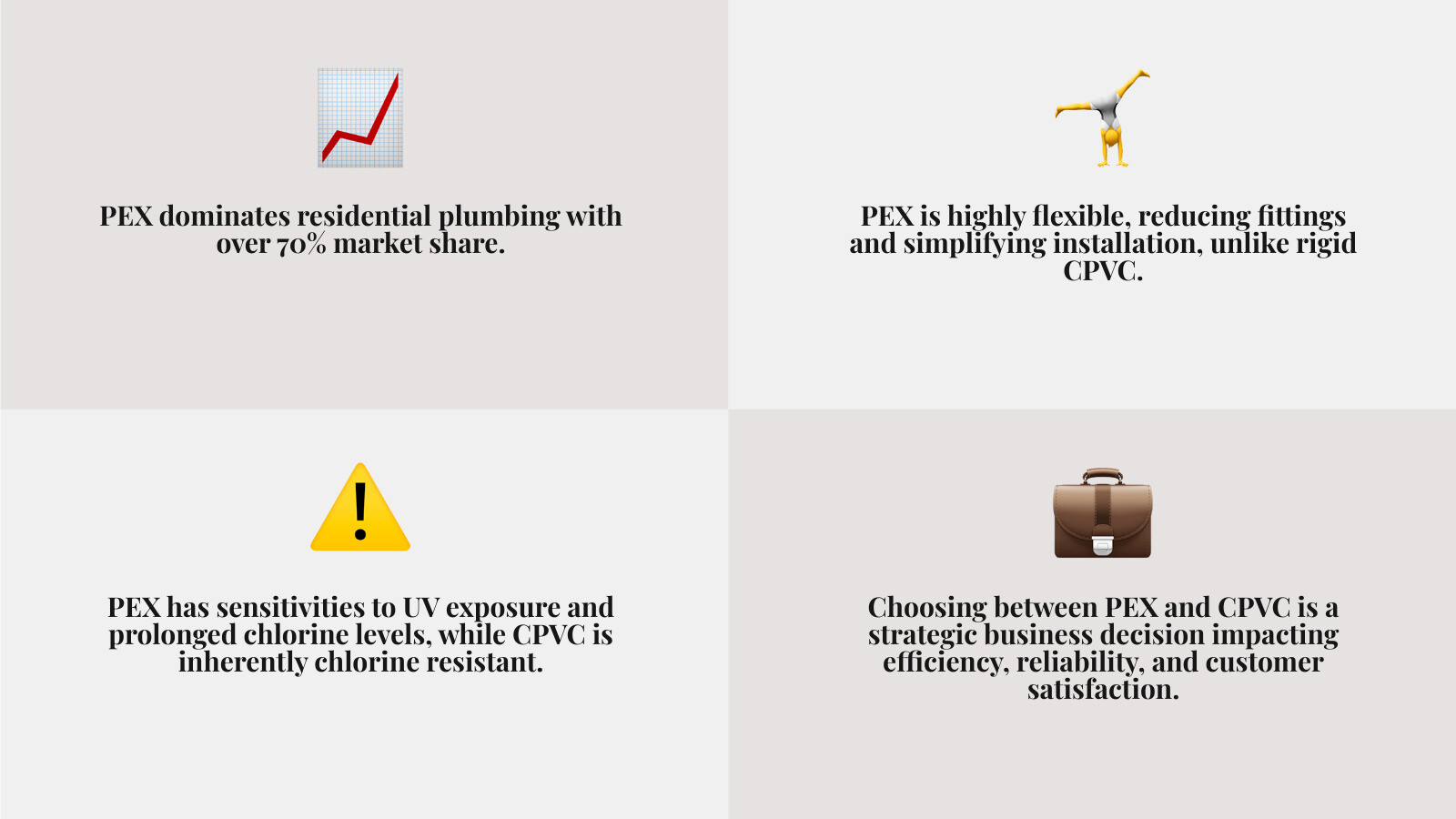

| Market Share | Dominant in residential plumbing (over 70%). | Niche market share (less than 15%). |

| Chlorine Resist. | Can be affected by high chlorine levels over time. | Inherently resistant to chlorine. |

| UV Resistance | Poor; not suitable for outdoor or exposed installations. | Better, but still requires protection for prolonged outdoor use. |

[sources: PlumbingSupply.com, Plastic Expert Group]

For HVAC and plumbing contractors, choosing between PEX vs CPVC isn't just about the material itself. It's a strategic business decision that impacts installation efficiency, long-term reliability, and ultimately, customer satisfaction.

PEX, or cross-linked polyethylene, is a flexible plastic tubing that has rapidly grown in popularity. It's known for its ease of installation and ability to bend around obstacles. CPVC, or chlorinated polyvinyl chloride, is a rigid thermoplastic pipe that has been a reliable choice for decades, particularly noted for its chemical resistance.

Both materials are widely accepted for plumbing systems, especially for potable hot and cold water distribution. However, their characteristics lead to vastly different project considerations for your team. From labor costs to tool investments and the final appearance, the choice impacts your bottom line and your reputation.

Consider the current landscape: In North America PEX holds about 70% of the residential plumbing market share, while CPVC holds about 15%. This shift reflects changing preferences and material advantages in modern construction and re-piping projects. Understanding these nuances helps us make informed choices that streamline our operations and deliver dependable results for our clients.

The Ultimate PEX vs CPVC Showdown for Contractors

When you're running a plumbing business, every job is a balancing act between efficiency, cost, and long-term reliability. The PEX vs CPVC debate isn't just about which pipe works better; it's about which choice helps your business thrive while keeping customers happy for decades to come.

Installation, Tools, and Project Costs

Let's be honest: installation ease can make or break your profit margins on a job. This is where the fundamental differences between these materials really show up in your bottom line.

PEX flexibility is its superpower. You can snake it through walls, around corners, and through tight spaces without breaking a sweat. With a bend radius as tight as 3.5 inches for 1/2-inch tubing, you'll use significantly fewer fittings compared to CPVC's rigid 18-inch minimum bend radius. Less fittings means fewer potential leak points and faster rough-in work.

The connection process tells a different story for each material. PEX connection systems don't need torches, glues, or solvents—just crimp, clamp, or expand, and you're done. Rain or high humidity? No problem. Your connections won't be compromised by weather conditions.

CPVC's solvent cement process requires more planning. You'll need proper ventilation, dry conditions, and patience for curing times, especially in cold weather, where you might wait 24 hours before pressure testing. Weather sensitivity can turn a straightforward job into a scheduling nightmare.

Here's where things get interesting from a business perspective. Research shows that CPVC installs about 15% faster than PEX in its most common configuration, particularly on straight runs where its rigidity becomes an advantage. However, PEX fittings typically cost several times more than comparable CPVC fittings and can take 2-3 times longer to assemble.

Tool investment varies significantly between materials. PEX requires specialized crimping or expansion tools upfront, but eliminates ongoing costs for glues and solvents. CPVC keeps tool costs lower initially but adds recurring material expenses for primers and cements.

Labor costs and material costs need to be evaluated together for each project. While PEX fittings cost more individually, you'll typically need fewer of them. For large multi-story projects, some contractors report material cost savings of 50% or more with CPVC, while others prefer PEX's labor efficiency on complex retrofit work.

The key is understanding how these factors play out in your specific market and typical job types. Whether you choose PEX or CPVC, protecting your installations with comprehensive coverage like our warranty plans ensures both you and your customers have peace of mind.

Durability, Lifespan, and Common Failures

Your reputation depends on installations that last. Both materials are engineered for 50+ year lifespans when properly installed, but they each have specific vulnerabilities you need to understand.

PEX freeze resistance is legendary among contractors working in cold climates. The material can expand dramatically without bursting when water freezes inside—a huge advantage over CPVC's brittleness in freezing conditions. CPVC will crack and fail when subjected to freeze-thaw cycles, making it less suitable for unheated spaces or regions with harsh winters.

Both materials handle high temperatures well, with temperature ratings up to 200°F making them suitable for hot water distribution. However, chlorine exposure affects them differently. The use of chlorine-based disinfectants reduces the temperature rating of PEX by 40°F, dropping it from 180°F to 140°F in chlorinated water systems.

PEX UV sensitivity is a critical limitation. One month of UV exposure can reduce the time-to-failure of PEX by up to 21%, making it unsuitable for outdoor installations or areas with direct sunlight exposure without proper protection. CPVC offers better UV resistance, though it still requires protection for prolonged outdoor use.

CPVC chemical sensitivities present different challenges. The material can degrade when exposed to certain chemicals found in building materials—electrical wire insulation, computer cables, termite treatments, some caulks, solder flux, or spray foam insulation. This requires careful coordination with other trades during installation.

Chlorine degradation affects these materials differently. CPVC is inherently resistant to chlorine due to its chemical structure, while PEX performance can be significantly reduced by high chlorine levels, lifted pressures over 80 psi, or temperatures above 140°F in chlorinated water. For detailed technical information, check out more info on PEX service life.

A Deep Dive into PEX vs CPVC Performance and Water Quality

When customers ask about water pressure and quality, the technical differences between these materials become crucial selling points—or potential liability issues.

Water flow rates vary significantly between systems due to fitting design. PEX fittings can reduce the internal diameter of a 1/2-inch pipe by 21% to 35%, causing substantial pressure drops and reduced flow rates. A typical PEX fitting introduces 2-3 psi of pressure drop, while CPVC fittings introduce only about 0.3 psi.

This pressure drop difference becomes noticeable in homes with multiple fixtures running simultaneously. Customers may experience weaker shower pressure or slower-filling appliances with restrictive PEX systems compared to full-flow CPVC installations.

Drinking water safety is paramount, and both materials must meet strict standards. All plastics used in potable water systems must be certified by a third-party like NSF International to ensure they don't leach harmful substances into drinking water.

Biofilm growth and leaching concerns differ between materials. CPVC's non-permeable surface resists biofilm formation and prevents external contaminants from penetrating the pipe wall. Some PEX products have been found to leach regulated substances, including gasoline components, into drinking water, and not all PEX products maintain NSF 61 certification at lifted temperatures.

Permeability is another factor. PEX's permeable nature theoretically allows external contaminants to pass through the pipe wall, while CPVC's impermeable structure provides a complete barrier. The practical implications of this permeability are still debated, but it's worth discussing with quality-conscious customers.

For specific questions about water quality or system performance, our team provides comprehensive support. Check out our frequently asked questions for additional insights on protecting your installations and customers.

The Contractor's Verdict: Choosing the Right Pipe for the Job

After weighing all factors, the PEX vs CPVC decision comes down to matching material characteristics with specific project requirements and your business model.

| Feature | PEX | CPVC |

|---|---|---|

| Install Speed | Can be slower (fittings) | Can be faster (straight runs) |

| Tool Cost | Specialized tools | Glues/Solvents |

| Material Cost | Higher material/fitting cost | Lower material cost |

| Flexibility | High | Low |

| Durability | 50+ years, but susceptible to chlorine/UV; freeze resistant | 50+ years, but susceptible to chemical contact/freezing; chlorine resistant |

Recommending PEX makes sense for complex retrofits, tight spaces, and cold climate installations. Its flexibility reduces fitting count and installation time in challenging layouts. The freeze resistance provides peace of mind for customers with seasonal homes or unheated areas. New construction projects often benefit from PEX's ease of installation and reduced water hammer noise.

Recommending CPVC works well for large projects where material costs matter, straight-run installations, and applications requiring maximum chemical resistance. Its superior chlorine resistance and water flow characteristics appeal to customers focused on long-term water quality. Commercial applications often favor CPVC's proven track record and non-permeable properties.

Client education and managing expectations are crucial regardless of material choice. Explain how local water conditions, building design, and usage patterns influence performance. Discuss potential taste, odor, or pressure differences. For new construction vs re-pipe projects, different factors may drive the decision.

Aligning material choice with business goals means considering your crew's expertise, tool inventory, typical project types, and warranty obligations. The goal isn't finding the "perfect" material—it's delivering reliable, efficient systems that satisfy customers while supporting profitable operations.

Protect Your Installations and Your Reputation

When you're weighing PEX vs CPVC for your next project, this decision goes far beyond the pipe itself. It's about building a business that homeowners trust and recommend to their neighbors.

We've all been there – that sinking feeling when a client calls about a leak or failure months after we've completed a job. Even when we've done everything right, materials can fail due to manufacturing defects, unexpected water conditions, or simple wear over time. These callbacks don't just cost us money; they can damage the reputation we've worked years to build.

The reality is that protecting our installations means protecting our livelihood. Every satisfied customer becomes a walking advertisement for our business. Every warranty claim we handle professionally strengthens that relationship. But when material failures happen and we're scrambling to cover unexpected repair costs, it puts strain on both our finances and our client relationships.

This is where thinking beyond the initial installation pays dividends. By offering extended warranty protection, we're not just selling a service – we're selling peace of mind. Homeowners appreciate contractors who stand behind their work with comprehensive coverage that goes beyond basic guarantees.

Smart contractors understand that value-added services separate them from the competition. When you can offer a homeowner protection against unexpected mechanical breakdowns, including both parts and labor costs, you're positioning yourself as a partner in their home's long-term performance, not just someone who installs pipes and walks away.

At JB Warranties, we've designed our programs specifically for plumbing professionals who understand this principle. Our extended warranty solutions for plumbing contractors cover mechanical breakdowns with customizable, transferable plans that adapt to your business model and your clients' needs.

The combination of the right pipe choice and the right protection creates a winning formula. Whether you choose PEX for its flexibility or CPVC for its chemical resistance, backing that choice with comprehensive warranty coverage ensures your clients feel confident in their investment – and keep calling you for future projects.

Tommy Cue

Vice President of Strategic Partnerships at JB Warranties